Precision Tire Cutting

HPTC

A High Pressure Tire Cutter with waterjet cutting technology

- Preparation of thin sliced tire cross sections

- Cutting of complete tires and tire sections

- Perfect surface

- No grinding or polishing

- No closing of holes with grind

- Cutting of green tires or sealing jellies

- Cold cut – no heat implementation

- Parallel cuts or Ω-cuts

- Perfect cut of steel and textile layers – no ripping or blooming

- Environmental friendly water management and filtering

- 3D cutting capability

- Suitable for 2-wheelers, PCR, LTR, TBR

- Special OTR solutions available

Track preparation and analysis

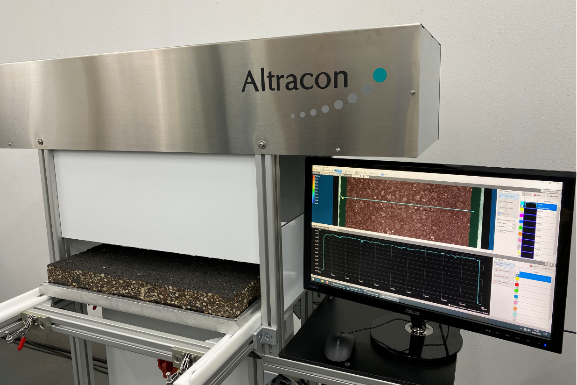

STS – Sample and Track Multi Scanner

Precision surface characteristic measurement indoor and outdoor

STS is the ultimate surface scanner for indoor and outdoor use. Switchable power supply and modularity allows most flexible use either for scanning surfaces such as tracks with the scan head positioned directly on the road or test track, or in the lab with the scan head applied to the sample intake where track cut-outs can be scanned which are mounted to the standard track carrier which is also used in LFT and HSLFT for friction testing.

Also rubber samples from HSLFT or LFT fit to the scanner to record their wear condition. This compatibility makes the STS also an ideal supplementation to Altracon’s friction testing equipment to rate the sample and track quality for testing.

A special image scanning function allows to also scan tire section cuts for quality control. This scanner is a real multi-talent.

- OUTDOOR track scanner

- INDOOR multifunctional scanner

- Roughness and structure determination

- HSLFT rubber-samples wear condition

- HSLFT track condition wear condition

- Tire section scanning

- others

SCU – Snow compression unit

Reproducible snow tracks for friction testing

The snow compression unit has been designed as a stationary machine for the production of snow tracks in track cassettes, which are used with the HSLFT. However, these track cassettes may be also used with other equipment.

Either natural or artificially produced snow will be filled into the system, which builds up snow layers under defined loading conditions. The system works computer controlled to generate flat tracks having homogeneous density for friction tests on snow surfaces with reproducible quality.

- HSLFT friction on snow

- others

Laboratory automation

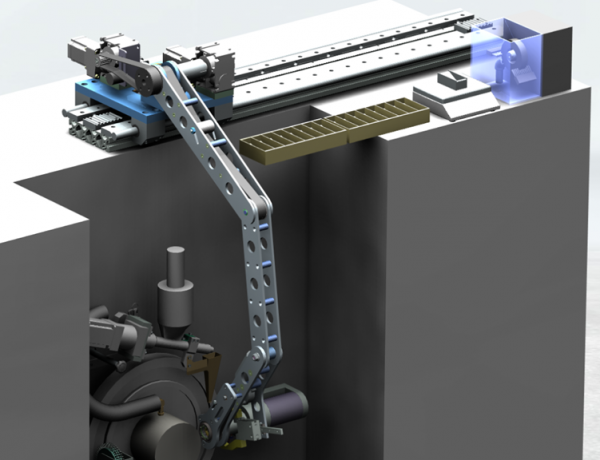

GAL – Grosch auto loader

Automate your Wear test machine

The GAL is a stationary loading unit, which extends the LAT100* GROSCH wear testing system. It is supplementary mounted to the machine and allows fully automated operation of the wear tests.

The GAL loads and unloads the LAT100 with samples, taken from a magazine located on top of the machine by use of a loading arm. The GAL control system communicates with the LAT100 control system and the companies test management system, which i.e. provides the information which sample to load and receives a log-file with the processing information. The GAL handles in addition the weighing of the sample after the test.

*) LAT 100 is manufactured by VMI.

- LAT 100 (VMI) Wear testing

- others